Prepared by: Shane Turner

Date: 26 September 2024

Executive Summary

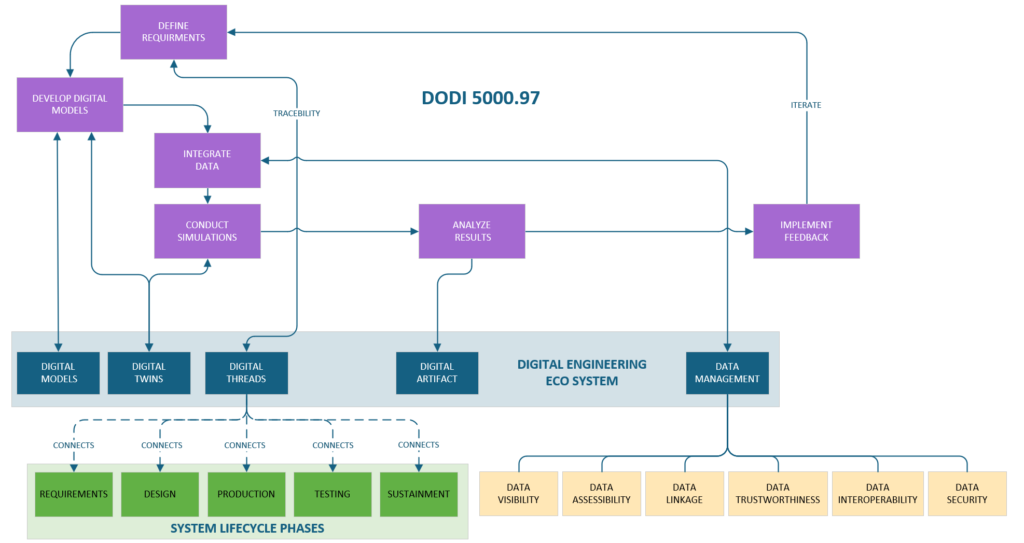

Digital Engineering (DE) is revolutionizing the design, testing, and maintenance of defense systems. Key components such as Digital Twins, advanced simulation environments, and collaborative digital platforms enable defense contractors to enhance system performance, reduce costs, and accelerate development timelines. Challenges like tool interoperability and cybersecurity must be addressed to fully realize these benefits. This paper outlines the critical aspects of DE, examines the challenges and opportunities for contractors, and provides strategic recommendations to align DE capabilities with the Department of Defense’s (DoD) modernization initiatives.

Introduction

Purpose

This paper analyzes how Digital Engineering (DE) supports the Department of Defense’s (DoD) modernization goals. It examines DE’s key components, identifies challenges and opportunities for defense contractors, and provides actionable insights for addressing common barriers, with a focus on tool interoperability and cybersecurity.

Background

The DoD’s ongoing modernization of defense systems increasingly relies on Digital Engineering for efficient, scalable, and secure development. DE technologies, including Digital Twins and advanced simulation platforms, are crucial for:

- Reducing development time

- Lowering costs

- Improving operational effectiveness

The complexity of modern defense systems necessitates a unified strategy to seamlessly and securely integrate advanced technologies. This paper explores how DE meets these challenges and drives innovation in the defense sector.

Key Components of Digital Engineering

Digital Twins

Digital Twins are virtual replicas of physical systems, continuously updated with real-time data from operational environments. In the defense sector, they offer powerful capabilities for system management, optimization, and innovation.

Key Applications

- Real-Time Monitoring

- Provides constant data feedback from operational systems

- Enables proactive monitoring and early issue detection

- Helps prevent costly failures through timely interventions

- Predictive Maintenance

- Utilizes advanced algorithms to analyze historical and real-time data

- Predicts potential component failures before they occur

- Allows for preventive maintenance scheduling

- Extends overall system lifespan and reduces downtime

- Virtual Testing and Design Optimization

- Enables testing of new configurations and upgrades in a digital environment

- Reduces physical prototyping and testing costs

- Accelerates design cycles and innovation

- Minimizes risks associated with implementing changes to physical assets

Advanced Simulation Environments

Advanced simulation environments allow defense contractors to virtually replicate real-world conditions and test system performance without physical prototypes. These environments are crucial for stress testing, system integration, and ensuring compatibility between subsystems.

- Virtual Prototyping: Facilitates building and testing prototypes digitally, identifying potential design flaws early and reducing the need for expensive physical prototypes.

- Stress Testing: Simulates environmental and operational stressors, ensuring systems perform reliably under real-world conditions.

- System Integration Testing: Allows testing of subsystem interactions, ensuring smooth integration without physical assembly at each design stage.

Collaborative Digital Platforms

Collaborative digital platforms enable teams to work together on the same digital models in real time, improving communication and reducing errors. These platforms are essential for defense contractors working with multiple teams across different locations and functions.

- Real-Time Collaboration: Permits simultaneous collaboration on digital designs, ensuring updates are shared immediately and avoiding miscommunication and version control issues.

- Global Integration: Facilitates collaboration across geographically dispersed teams, reducing the need for physical meetings and enhancing project efficiency.

- Version Control and Data Consistency: Ensures changes made by one team are immediately reflected for all, maintaining consistency across the project.

Challenges in Digital Engineering

Tool Interoperability

Ensuring that different DE tools work seamlessly with the DoD’s existing platforms is a significant challenge. Many current defense systems operate on legacy platforms, creating substantial integration hurdles.

- Legacy System Integration: Integrating modern DE tools with decades-old systems requires custom solutions and technical expertise.

- Cross-Vendor Compatibility: Large defense projects often involve multiple contractors using different DE tools. Seamless data transfer and compatibility across vendor platforms are critical for success.

- Standardization Needs: The lack of standardization in data formats and interfaces complicates integration. Establishing standardized protocols can enhance compatibility and streamline collaboration.

Cybersecurity in Digital Engineering

The shift towards digital models and simulations increases the risk of cyberattacks. Protecting sensitive defense data is a top priority, necessitating the integration of cybersecurity into every aspect of Digital Engineering.

- Data Security and Breaches: Digital platforms store sensitive data that must be protected from cyber threats. Implementing robust encryption and secure data management is essential.

- Secure Access Control: Restricting access to authorized personnel safeguards defense technologies. Establishing secure access measures is crucial.

- Cybersecurity Compliance: Compliance with frameworks like the Cybersecurity Maturity Model Certification (CMMC) is mandatory. Ensuring DE platforms meet or exceed these requirements is imperative.

- Resilience and Recovery: Having recovery protocols and backup systems minimizes downtime and data loss in the event of a cyberattack.

Opportunities for Contractors in the Defense Industry

As the Department of Defense (DoD) continues to modernize its digital ecosystem, contractors face unique opportunities to differentiate themselves and secure long-term partnerships. This document outlines three key areas where contractors can focus their efforts to gain a competitive edge.

Developing Custom Interoperability Solutions

The defense industry often grapples with integrating modern Digital Engineering (DE) tools into legacy systems. Contractors who can bridge this gap stand to gain significant advantages.

- Create middleware solutions that enable seamless data exchange between new DE tools and older systems

- Develop APIs that allow legacy software to interact with modern cloud-based platforms

- Design and implement data translation layers to ensure consistency across disparate systems

- By reducing integration delays, contractors can help the DoD save an estimated 20-30% on project timelines and costs, according to a 2023 GAO report on defense acquisitions.

Leading in Cybersecurity

With cyber threats evolving rapidly, the DoD places a premium on partners who can deliver secure, compliant DE environments.

- Implement zero-trust architecture in DE solutions

- Develop AI-powered threat detection systems tailored for defense applications

- Create secure cloud enclaves that meet or exceed DoD security standards

Contractors with strong cybersecurity credentials are 2.5 times more likely to win long-term DoD contracts, based on a 2024 survey of defense procurement officers.

Advocating for Standardization

As the defense industry moves towards greater interoperability, contractors who contribute to standardization efforts position themselves as thought leaders.

- Participate in industry working groups focused on developing common data exchange formats

- Contribute to open-source projects that align with DoD interoperability goals

- Develop and promote best practices for implementing MOSA (Modular Open Systems Approach) in defense projects

Contractors involved in successful standardization initiatives report a 40% increase in new business opportunities within 18 months, according to a 2024 industry analysis.

By focusing on these three areas – interoperability, cybersecurity, and standardization – contractors can significantly enhance their value proposition to the DoD. To capitalize on these opportunities, consider the following next steps:

- Assess your current capabilities in each area

- Identify specific projects or initiatives that align with these opportunities

- Invest in talent and resources to build expertise in these critical domains

- Engage with industry partners and DoD stakeholders to stay informed of evolving needs and standards

Contractors who successfully navigate these opportunities will be well-positioned to secure long-term partnerships and play a pivotal role in shaping the future of defense technology.

Strategic Recommendations for Digital Engineering in Defense

1. Invest in Interoperable DE Tools

Rationale:

- Ensures compatibility with both modern and legacy systems

- Facilitates smoother integration with DoD platforms

- Prevents costly delays and compatibility issues

Action Items:

- Conduct a comprehensive audit of existing DE tools and their compatibility

- Develop or acquire tools that bridge the gap between legacy and modern systems

- Implement middleware solutions for enhanced interoperability

- Regularly update tools to maintain compatibility with evolving DoD standards

2. Strengthen Cybersecurity Measures

Rationale:

- Protects sensitive defense information and systems

- Positions contractors as industry leaders in secure DE practices

- Ensures compliance with stringent DoD cybersecurity standards

Action Items:

- Embed cybersecurity best practices into DE platforms from the design phase

- Implement robust encryption and access control mechanisms

- Conduct regular security audits and penetration testing

- Develop a incident response plan specific to DE systems

- Provide ongoing cybersecurity training for all personnel involved in DE projects

3. Focus on Industry Standardization

Rationale:

- Leads the industry towards more efficient and collaborative project execution

- Makes contractors more attractive partners to the DoD

- Reduces long-term costs and improves interoperability across the defense sector

Action Items:

- Actively participate in industry working groups focused on DE standardization

- Contribute to the development of open standards for DE in defense

- Align internal processes with emerging industry standards

- Advocate for the adoption of standardized DE protocols within the defense community

- Develop case studies demonstrating the benefits of standardized DE approaches

4. Invest in Workforce Development

Rationale:

- Ensures a skilled workforce capable of leveraging advanced DE tools

- Maintains competitive edge in rapidly evolving technological landscape

- Attracts and retains top talent in the field

Action Items:

- Establish partnerships with universities to develop DE-focused curricula

- Create internal training programs to upskill existing workforce

- Implement mentorship programs pairing experienced DE professionals with new hires

- Encourage continuous learning and certification in relevant DE technologies

5. Embrace Model-Based Systems Engineering (MBSE)

Rationale:

- Aligns with DoD’s push towards model-centric approaches

- Improves system design, analysis, and verification processes

- Enhances collaboration and communication across multidisciplinary teams

Action Items:

- Transition from document-centric to model-centric engineering processes

- Invest in MBSE tools and methodologies

- Develop best practices for integrating MBSE with other DE initiatives

- Create a roadmap for full MBSE adoption across all relevant projects

Conclusion

Digital Engineering offers significant advantages for defense contractors, including reduced development time, lower costs, and enhanced collaboration. To fully capitalize on these benefits, contractors must address tool interoperability and cybersecurity challenges. Offering custom interoperability solutions, secure DE environments, and contributing to industry-wide standardization efforts will position contractors as essential partners in the DoD’s modernization strategy.

By leveraging Digital Twins, advanced simulations, and collaborative platforms, contractors can help the DoD achieve its modernization goals while securing their place in a rapidly evolving defense industry.

Benefits for Defense Contractors and DoD Engineers

- Improved system performance and reliability

- Cost savings through optimized maintenance and reduced downtime

- Enhanced decision-making based on data-driven insights

- Faster development and deployment of system upgrades

- Increased operational readiness of defense assets

References

- Defense News Whitepaper: Ground Vehicle Modernization

- DoD Aviation Integration Newsletter, 1st, 2nd & 3rd Editions